LVS-9580 Portable Barcode Verification System

The LVS-9580 is now available in a version that can verify codes as tiny as 2 mil, the LVS-9580 is a versatile, high-performance solution for off-line barcode verification to ISO/IEC and MIL-STD-130N standards. Featuring a high-resolution 5.0 megapixel camera, the LVS-9580 reads and analyzes linear (1D) and two-dimensional (2D) barcodes up to 3.0 inches (76.19 mm) wide and up to 2.25 inches (57.15 mm) tall.

The LVS-9580 is now available in a version that can verify codes as tiny as 2 mil, the LVS-9580 is a versatile, high-performance solution for off-line barcode verification to ISO/IEC and MIL-STD-130N standards. Featuring a high-resolution 5.0 megapixel camera, the LVS-9580 reads and analyzes linear (1D) and two-dimensional (2D) barcodes up to 3.0 inches (76.19 mm) wide and up to 2.25 inches (57.15 mm) tall.

The new update that adds a high-definition lens with ultra-low distortion addresses recent and rapid improvements in laser marking technology. Direct part markings (DPMs) can now be much smaller than before, giving consumer electronics and medical device manufacturers more options for code placement. With verification capabilities matching marking capabilities, manufacturers take full advantage of the flexibility offered by today’s laser-marked codes.

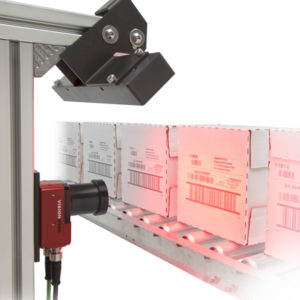

Powered by a 10-foot (3.0 m) USB 2.0 cable, the LVS-9580 verifies barcode labels and direct part marks (DPM) located on a wide range of surfaces including corrugated cardboard boxes, shipping containers, plastics, composites, and metal surfaces.

The LVS-9580 verifies multiple barcode types, including any combination of linear, 2D (Data Matrix, QR Code, and Aztec Code), and stacked linear (PDF 417, Micro PDF and Composite Codes). Feel free to contact us for a detailed list of supported standards and symbologies supported by the LVS-9580.

Additional features:

- 21 CFR Part 11 Compliant-Ready

- Certified by GS1 US

- Verification of 1D/2D codes and direct park marks

- Inspection: Inspects all nine of the ISO (ANSI) parameters in linear (1D) codes, plus added features of determining blemishes and human readable validation. The LVS-9580 also verifies 2D codes (including multi-row and matrix codes) and reports all parameters as specified in the applicable ISO/IEC and MIL-STD-130N specifications.

- Detailed Reporting: Analysis is color coded to show exactly where the problem is located within the barcode, and sections of the barcode can be analyzed to determine how to solve the problem.

- High-Resolution Inspection: High-resolution inspection of the barcode is possible due to the use of a 5.0 megapixel high resolution camera, which allows reading and analyzing every two thousandth of an inch (.002″/.05 mm) of the barcode height; this exceeds the minimum ten-scan average required by ISO.

- Advanced Technology: Sensor technology allows more detailed analysis of the barcode, and makes reading of small and truncated codes possible, accurate and easy.

- EAN/UPC NIST Traceable Calibrated Conformance Standard Test Card: The LVS-9580 is supplied with a NIST traceable calibrated conformance standard test card to ensure that the system is always within a known calibration standard.

- The LVS-9580 was formerly known as the Integra 9580 by Label Vision Systems.

Reviews

There are no reviews yet.