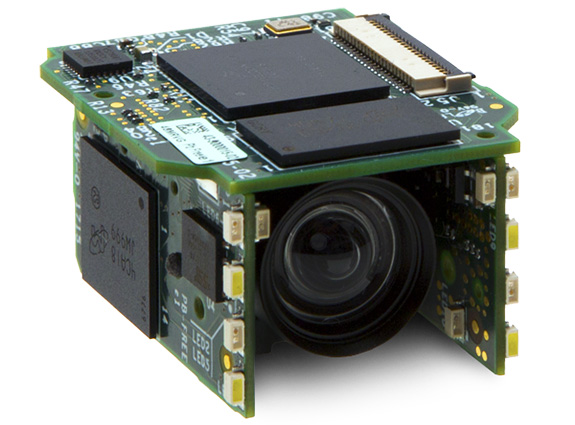

Modular OEM Imaging Engine

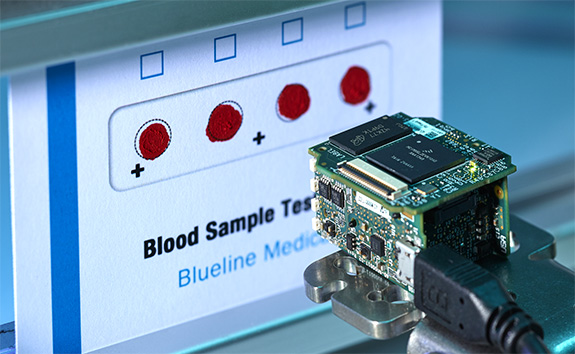

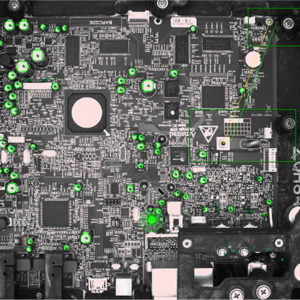

The MicroHAWK® Engine offers OEMs and machine builders the industry’s smallest, most powerful, modular, and scalable smart camera platform available for solving barcode and machine vision application challenges.

The design of the MicroHAWK Engine builds upon Omron Microscan’s 30+ years of experience working with the world’s largest OEMs. MicroHAWK allows nearly endless combinations of easy-to-use software tools, optics, sensors, and processor performance to meet any OEM application requirement. Extremely small, powerful, and simple – MicroHAWK is the only solution for your embedded application.

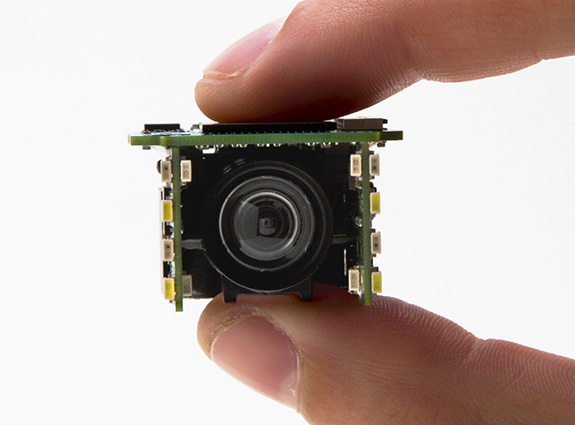

Ultra-Compact

Measuring just 19.5 mm x 28.7 mm x 33.9 mm and weighing less than 14 g, the MicroHAWK Engine is intended for embedding inside instruments, automation machines, or on robotic equipment.

Extremely Powerful

Built around an ultra-fast microprocessor, MicroHAWK easily solves application challenges ranging from simple barcode reading to intensive machine vision inspections that typically require smart cameras 10 times its size.

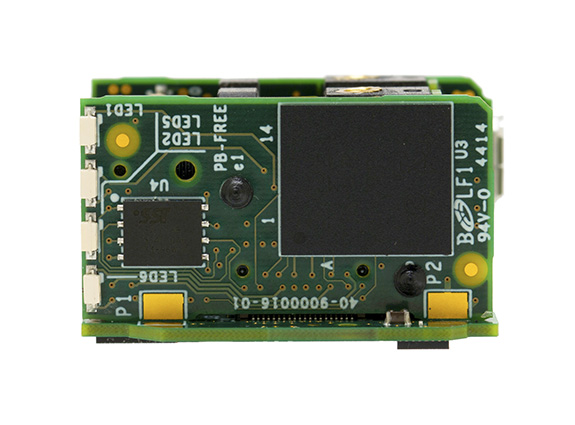

Highly Modular

The MicroHAWK Engine’s comprehensive tool set – barcode reading and/or machine vision software, optics, sensor, illumination, and an IP-rated enclosure – allows you virtually unlimited flexibility in configuring your application.

Reliability and Longevity

MicroHAWK delivers both reliability and high performance with the assurance of long-term availability and support. Omron Microscan has served the OEM/Embedded market for over 30 years and we have a sophisticated understanding of the service and support required for the lifecycle of your machine.

Scalable Vision Software

The MicroHAWK Engine runs the full suite of Omron Microscan machine vision tools. AutoVISION software provides an intuitive interface, step-by-step guides, and a library of presets that allow easy set up and deployment. Visionscape software is available for advanced users and more complex applications.

MicroHAWK Engine: Capabilities

- 1D/2D symbol decoding

- Optical Character Recognition (OCR)

- Symbol Quality Verification and OCV

- Dynamic part location

- Assembly verification

- Dimensional measurements

Plus Visionscape Option

- Image transformation and scaling

- Precision calibration

- Custom vision tools (scripting)

- Program Control functions

- 50+ machine vision tools

Reviews

There are no reviews yet.