PRINTING

PRESS

CONTROLS

INDUSTRIAL

CONTROLS

AND INSPECTION

Sidewinder Specifications:

Device Type: Anti-Wrap System

Voltage: 380—600 VAC 3-Phase

Drive: Indramat IndraDrive

Motor: Indramat IndraDyn S Synchronous Servo

Display (HMI): 4 x 20 Character LCD Backlit

Arming Signal: 20% Press Speed Contact

Press Speed: Press Encoder (Multiple Formats Available)

Frame: All Aluminum Construction

Frame Size: 8” (203mm) x 30” (762mm) x Web Width Plus 24” (610mm)

Anti-Wrap Roll: High Speed Balanced 4” (102mm) Aluminum Slotted Roller

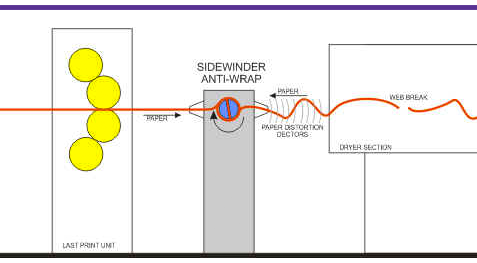

How Does The Sidewinder Work?

What Makes The Sidewinder Unique?

The Sidewinder’s servo drive is activated only during a web break. Within milliseconds after the break, the servo drive rotates the slotted anti-wrap roller to a given speed as calculated by its proprietary speed-matching algorithm. The servo drive control then matches and follows press speed down to zero all while the anti-wrap section pulls the paper from the last print unit preventing a wrap-up. The patented* “Lock & Roll” roller design ensures positive web captures. The dispensed paper is neatly wound around the anti-wrap roller for easy removal.

Sidewinder Operation Sequence

1) Aniti-Wrap Arms at 20% Press Speed

2) Distortion Detectors Monitor Paper

3) Distortion Detected at Dryer

4) Anti-Wrap Roller Activated

5) Roller Spins Gathering Paper

6) Optional Web Severer Fires

7) Press Stops

8) Operator Opens Guard and Removes Paper

9) Operator Closes Guard

10) Anti-Wrap Roller Auto Positions for Web Up